Advanced Heat Trace Solutions

Technology Platform

Advanced Heat Trace Solutions

Technology Platform

A Revolutionary Technical Leap in Self-Regulating Heating Cable: Size Reimagined

1. VTR’s Technical Breakthrough: What is the Innovation?

For decades, engineers and designers have been limited by the physical constraints of traditional heating elements—often bulky, flat, or stiff—which severely restricted their integration into modern, complex product structures. E-POLY’s VineTrace-VTR shatters this limitation with a foundational technological leap: transforming conventional self-regulating technology into an ultra-slim, highly flexible Ø4.5mm round profile.

This innovation is not merely a size reduction; it is a complete design liberation:

From Bulk to Micro-Profile: VTR successfully evolves the core components of the self-regulating element into a micro-sized form factor.

Unprecedented Flexibility: The perfect round geometry grants VTR true all-angle bending capability, allowing it to be seamlessly routed into extremely tight clearances, complex contours, and sharp edges where traditional, larger cables could never fit.

This breakthrough brings the safety and efficiency of self-regulating heat to applications demanding the highest levels of design aesthetic and structural integration.

| Feature | Traditional Flat/Thick Cable | VineTrace-VTR (VTR) |

|---|---|---|

| Profile & Size | Large, bulky, rigid profile (e.g., flat or thick round) | Ultra-slim ∅4.5mm Round |

| Bending/Routing | Limited radius, complex to route | 360∘ Flexible, highly adaptable to corners |

| Overheating Safety | Self-regulating (PTC) is safe, but bulk restricts tight placement | Zero Overheating Risk even if crossed/overlapped |

| Installation | Requires precise sizing, time-consuming placement | Cut-to-Length on site, quick embedding |

2. Core Technical Advantages and Features

How does VTR maximize efficiency and adaptability with medium-low power?

Maximum Safety (PTC): VTR’s Positive Temperature Coefficient (PTC) technology guarantees that the power output automatically decreases as the ambient temperature rises. This innate safety feature allows VTR to be used in close proximity applications, such as embedded in high-end electric blankets and personal heating products, where zero overheating risk is paramount.

Adaptive Energy Efficiency: The intelligent power regulation ensures that heat is generated only where and when needed, based on the ambient environment. This dynamic adjustment significantly reduces energy consumption compared to fixed-wattage cables.

Highly Adaptable Installation:

Cut-to-Length Simplicity: VTR can be cut precisely on-site to any required length without altering its power output per meter. This flexibility simplifies inventory, reduces waste, and eliminates the need for detailed prior measurements.

Ideal for Complex Structures: The round shape and pliability allow VTR to be highly adapted to demanding installation environments.

3. Thin-Round Wire Self-Regulating Applications in Future

Frame Heating

Mouse Hover ↖︎

High-Performance Building Structures

☑Thermal Management Solved

☑skywindow

☑skywindow

☑ Anti-Condensation/forest

Cold Chain and Refrigeration Equipmen

Mouse Hover ↖︎

Simplified Defrosting and Inventory Optimization

☑cut-to-length

☑no longer need dozens of complex SKUs

☑Energy Savings and Reliability

☑ precise heat for defrosting

Personal Soft Heating Products

Mouse Hover ↖︎

Personal Soft Heating Products

☑Ultimate Safety and Comfort

☑electric blankets

☑zero risk of overheating

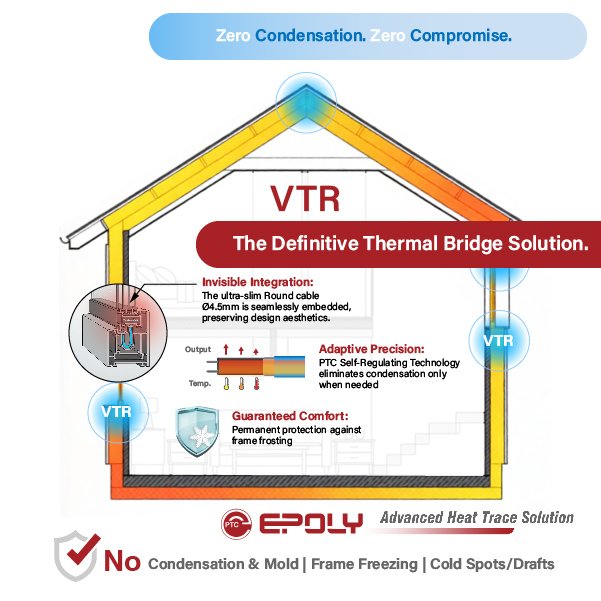

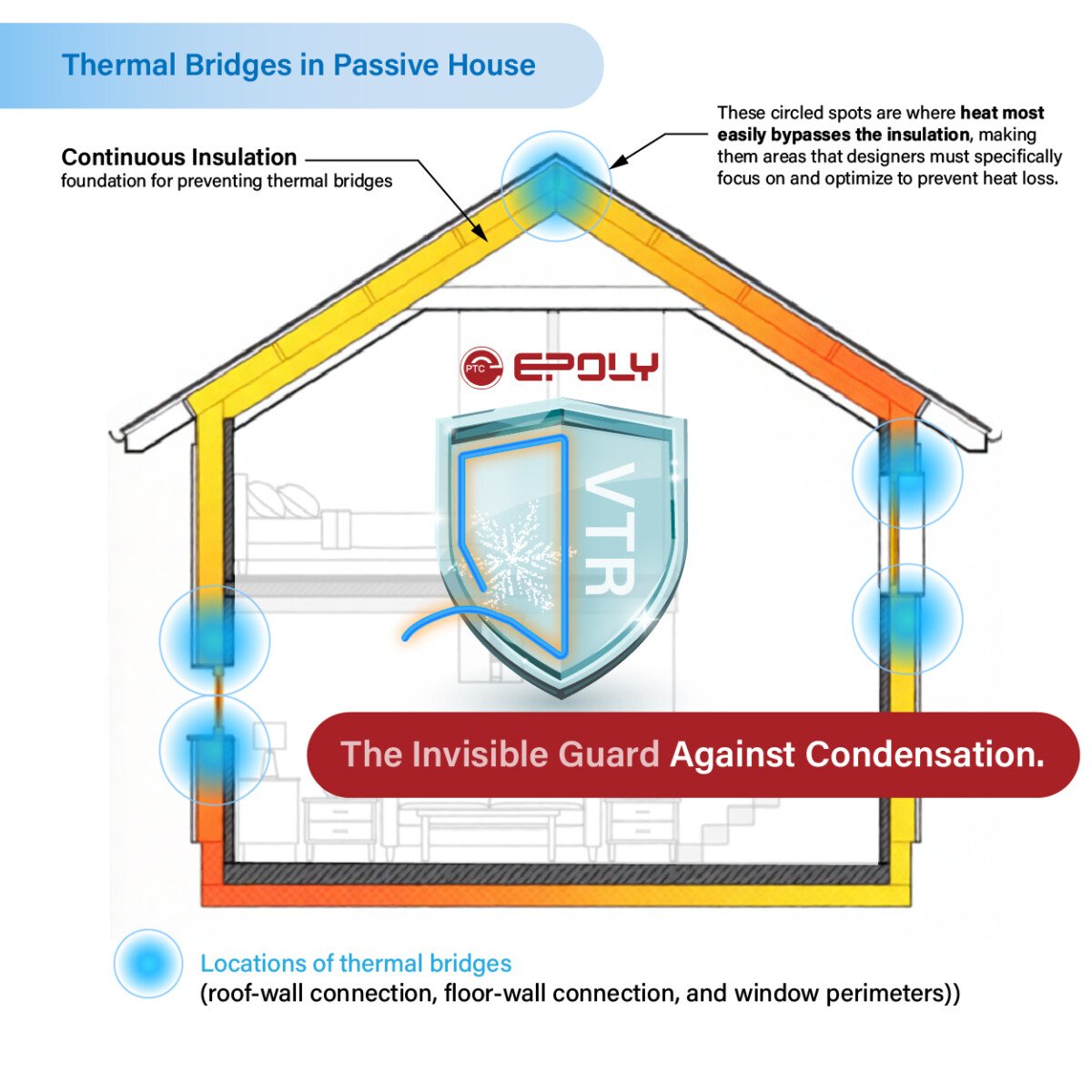

A. High-Performance Building Envelope (Frame Heating)

VTR is the definitive Frame Heater solution for eliminating condensation and ensuring structural functionality in advanced construction:

Condensation & Mold Prevention: Easily embedded into the narrow gaps and edges of window and door frames, VTR eliminates cold spots, prevents moisture build-up, and stops mold and structural decay—critical for maintaining air quality in Passive House environments.

Operational Reliability: By installing seamlessly into the edge of closing mechanisms, VTR prevents ice accumulation on key components like skylight frames and emergency egress doors, guaranteeing they remain functional and operational in extreme cold.

B. Commercial & Industrial Cold Chain

VTR drastically simplifies the process of thermal management for refrigeration systems:

Simplified Defrosting for Cold Cabinets: For commercial freezers and display cases, VTR’s cut-to-length feature is transformative. Manufacturers no longer need to manage a vast, complex range of SKUs corresponding to every single door dimension, dramatically streamlining production and supply chain management.

Energy-Saving Defrost: The adaptive power output ensures that the defrosting energy is applied precisely and efficiently, leading to significant energy savings in continuous cold storage operation.

C. Applications in Personal Soft Heating Products

Ultimate Safety and Comfort: VTR’s ultra-slim round profile, flexibility, and absolute zero-overheating safety feature make it an ideal core component for next-generation personal heating products.

Use Cases: Perfect for applications in high-performance electric blankets, heated apparel, and other products requiring zero risk of overheating and high bending adaptability.

4. Conclusion: Why VTR is the Smarter Choice

What is the return on investment? VTR offers a platform for innovation, allowing for design aesthetics to be preserved while ensuring functional reliability. It delivers energy-efficient, adaptive heating that achieves two primary goals: guaranteeing functional de-icing in winter and effectively preventing mold and moisture damage year-round.

Manufacturing Excellence

E-POLY Technology-Advanced Heat Trace Solutions

E-POLY is a manufacturer of Heat Trace Cable, dedicated in the design and manufacturing of trace heating cable for snow melting, roof de-icing, pipe freeze protection, radiant floor heating and process heating.No.12, Lingbo Road, Economic Development Area, Gaoyou City, Jiangsu Province, China. All rights reserved.